Your Reliance Metal Roofing Solutions

- The raw material is prepainted steel, aluminum, galvanized steel, galvalume, Aluzinc, etc.

- Material width is up to 1,500mm full hard

- The thickness range is between 0.15 to 1.0mm

- Variety metal roofing designs according to your drawings

- Line speed up to 40-50m/min.

- Integrated roofing sheet manufacturing solutions

Reliance Roof Roll Forming Machines Assure Your Metal Roofing Sheet Quality Perfect

Custom Your Own Roof Roll Forming Machines

Metal roofing is widely used for commercial & residential building and construction industry. Through different roll forming dies, our roof roll forming machine can achieve different kinds of roofing sheets. Reliance can custom design the roof forming machine according to your profile drawings. To successfully startup this business, you have to work with a reliable roof roll forming machine manufacturer from China. It’s also named roof panel machine, roofing machine, steel roofing machine, roof forming machine, roof panel roll forming machine, etc.

As a leading roof roll forming machine manufacturer in China, Reliance has been in the roof roll forming machine design and manufacturing over ten years. Reliance can custom any types of roof panel machines, such as trapezoidal roof, corrugated metal roofing, standing seam metal roof, IBR roof sheeting, aluminum roof, R roof panel, curved roof, trimdek roofing, etc. No matter whether you have experience in this filed before, we will help you 100% startup this business. Please don’t hesitate to contact us if you need further information.

Reliance Roof Roll Forming Machine Use the Famous Brand For Critical Parts

Your Professional Roof Roll Forming Machine Manufacturer

The trapezoidal roof is with ribbed trapezoidal shapes across the metal roof panel. It’s a mechanically seamed roofing panel used for industrial, commercial, and large span buildings over steel purlins.

Reliance trapezoidal roof roll forming machine can produce various dimensions, raw materials, high strength G550 trapezoidal roof sheets according to your market need.

Corrugated metal roofing is with sinusoidal wave shapes across the roofing panel. Corrugated roofing is generally used in commercial and residential buildings. Reliance corrugated metal roofing roll forming machine can produce various dimensions, raw materials, high strength G550 corrugated roof sheets according to your drawings.

Reliance can produce corrugated metal roof in 0.18-0.8mm thickness and full hard material.

Standing seam metal roofing is a concealed type metal roofing system. It features with vertical ridges and a flat area with small stiffens. The unique interlocking design forms the tight overlapping; no rivets or screws are exposed on the surface of the panels. Reliance Standing seam metal roof Roll Forming Machine can proceed with different kinds of standing seam roofs, aluminum alloy, galvanized steel, prepainted steel, full hard G550 material.

Reliance standing seam metal roof roll forming machine can produce standing seam metal roofs in different kinds of material and up to 1.2mm thickness.

IBR roof sheeting is trapezoidal shape roof or side cladding with effective coverage width of 686mm. IBR roof panel the most popular used roofing sheet in Africa countries. The profile is with a high strength-to-weight ratio, best load span consistency, and effective drainage. Reliance IBR Roof sheeting roll forming machine can proceed aluminum alloy, prepainted steel, galvalume, with full hard G550 standard.

Reliance IBR 686 roof sheeting roll forming machine can be suitable for different kinds of material and thickness.

When making roof sheeting, the aluminum roof is more corrosion-resistant than a steel roof. Aluminum roof sheeting is lighter and softer than the steel roof. Besides, it’s less weight roof on your house’s structure. Reliance aluminum roof roll forming machine can produce various profiles, different thickness according to your requirement.

Reliance aluminum roof roll forming machine can produce the various design of aluminum roof in max. 1.2mm thickness.

R roof panel is a low slope metal roof and wall panel with 1.25″ height ribs and 12″ pitch corrugation. It’s used primarily in the prefabricated metal building system. Reliance R roof panel roll forming machine is a good solution for high-quality R roof panel productions.

Reliance R panel roof roll forming machine is uniquely designed to make R panel.

Curved roof sheets are more used according to new building design concepts or to create a unique roof. It’s also called arched metal roof with large span and concave, convex, and S shape curved. Reliance can provide curving machines to curve various roofs in the required radius.

Reliance curved roof roll forming machine can convert the curved panel through the flat roof panel.

Double layer, double-deck, or dual level is the design that can make two kinds of the roof in one roll forming machine. This design saves floor space and cost-efficiency. Reliance double layer roof roll forming machine is with robust design, strong structure, and customized roof shapes.

Reliance double layer roof roll forming machine can make both types roofs in one machine to save cost and floor space.

Cassette type or rafted type is the design suitable for various roofs design in one machine. There is a basic machine platform which is with enough wide and roll forming space. In the future, if you need to invest new profiles, you will need to order a new cassette unit or rated units and shear blade. Reliance cassette type roof roll forming machine can help you to achieve to produce more than ten kinds of roofs in one machine. It will save the cost to invest new separate roof roll forming machine. To meet the new market need, you will be able to be flexible to increase new roof design.

Reliance cassette type or rated type roof roll forming machine can make various designs of roof in one machine through changing the whole rafted units.

Why Reliance Roof Roll Forming Machine

- To meet different requirements, we develop the following types of roof panel roll forming machine.

- A double layer roof roll forming machine can make both roof profiles by one machine.

- Cassette type roof roll forming machine can make more than two kinds of profiles. In the future, if you need to develop a new kind of roof, you need just buy new cassette units and cutting blades.

- To meet the high capacity requirements, our high-speed 50m/min line can highly improve capacity.

- For different automation levels, our machine combines the uncoiling, pre-cut, PVC-filming, stacking function in one roof roll forming machine.

- To improve the response time and cost, we developed a remote control system. Through this system, our engineer can analyze the machine in China and revise the program very quickly.

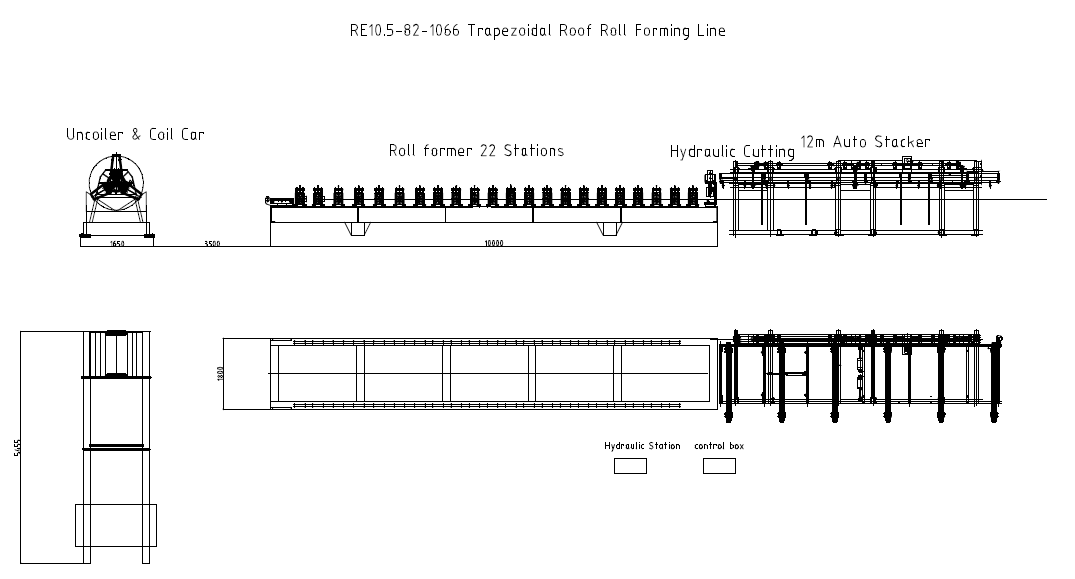

- Parameters ( Datasheet )

- Equipment List

- Layout Drawing

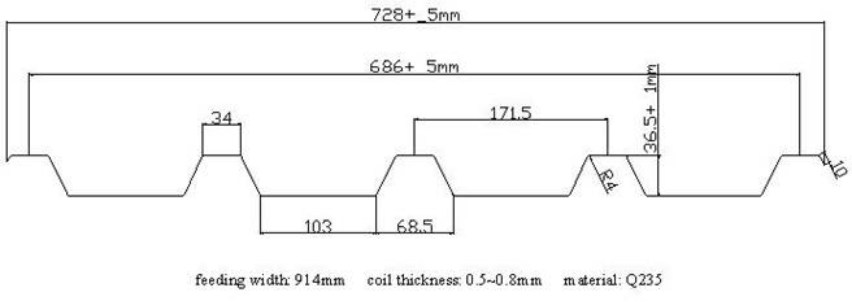

- Profile drawing

| Technical Parameters | ||||

| 1 | Suitable Material | PrepaintedSteel Coil / Galvalume Steel Coil / Embossed Aluminum Coil | ||

| 2 | Material Width | Common use 914/ 1000 /1200/ 1220 / 1250mm | ||

| 3 | Material Thickness | 0.3-0.8mm | ||

| 4 | Roll forming speed | Common speed 15m/min, Up to 50 m/min (Exclude Cutting Time) | ||

| Equipment List | ||||

| 1 | Hydraulic decoiler with loading coil car | 1 set | ||

| 2 | Rollformerwith tooling | 1 set | ||

| 3 | Hydraulic cutting | 1 set | ||

| 4 | Run out table or automatic stacker | 1 set | ||

| 5 | Siemens Or MitsubishiPLC and Touchable Screen | 1 set | ||