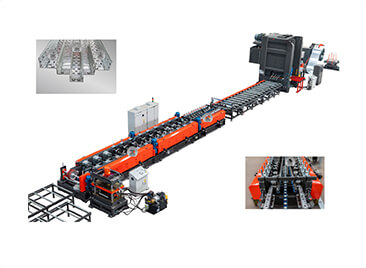

Turn Key Solutions For Your Roll Forming Machine

Reliance machinery is a reliable and trusted roll forming machine China manufacturer through customized turnkey solutions. There are wide ranges of applications for cold roll forming machines. Turnkey solutions will help customers to save time and cost for setting up the new business. For different profiles, it will also need to integrate some functions, like notching, welding, bending, printing, and stacking, etc. Reliance roll forming machinery experts will make a suitable proposal according to customers’ requirements and get the best throughout. Reliance machinery strives to be the best turnkey customized solutions for roll forming machine. The process of quality control will start at consulting, manufacturing, testing, installation, and aftersales service.

Free Consultation

Our services include a free consultation to ensure you get the right roll forming machine for making the correct products you need.

Custom Manufacturing

To adapt to different roll forming needs and budgets, Reliance Machinery provides customized solutions according to each customer. We continuously innovate to meet our clients’ needs and exceed their expectations.

Trial Running Before Shipment

Before shipment, Reliance machinery will make trail running for each machine to assure the machine quality.

Installation, Commissioning & Training

The Reliance engineer team will provide overseas service for roll forming machine installation, commissioning, and training. It will ensure the final quality and successfully set up the production.

Roll Forming Machine Specialist in China

At Reliance Machinery, superior quality is everyone’s responsibility.

Reliance strives to make continuous improvement processes to achieve the highest level of quality possible. We are focus on every step improvement and to be the trusted roll forming machine manufacturers. Our roll forming machines ensure the high quality of output profiles based on different kinds of materials or profiles.

- Raw material. For roll forming machines, the most important parts are rollers, shafts, housing, machine base, bearings and roller chains, or gearboxes. For all these parts, we select the top quality material suppliers.

- High precision machining. Reliance uses advanced machine tools to make sure every part with high tolerance and with excellent performance. It will ensure the roll forming machine produces high-quality products.

- Reliance has a strict quality control team. After machine installation, full testing is a necessary step to check the quality of the final product.

- Reliance experienced engineer team will consider carefully for machine design and assure the machine design is perfect.

- Innovative design will help to provide the best solutions and give added value features.

Get Free Consultation

Roll forming machines are highly stable and high-efficiency metal fabrication technology applied across many industries. Below listed are standard or customized roll forming machines we’ve made before.

Reliance Manufacturing Capability

- Material Type: Prepainted Steel, Galvanized Steel, Galvalume, Aluminium, Stainless Steel, Cold Rolled Steel, Hot Rolled Steel, etc

- Thickness Range: 0.14mm to 16mm

- Width Range: Max. 1500mm

- Tolerance: +/-0.2mm

- Yield Strength: Max. 650Mpa

- Line Speed: Max. 75m/min

Quality Assurance of Roll Forming Machine

- Material Certificate: Chemical composition from the steel factory for raw material.

- Heat Treatment: Harden Treatment Report for roller tooling, mould, mechanical parts.

- Trial Run Before Shipment: Automatic testing with regular production.

- Brand Spare Part: Imported brand parts.

Why Reliance Can be Trusted by 500+ Clients

15 Plus Years Experience

Reliance engineers team have more than 15+ years of experience in designing and manufacturing roll forming machines. Reliance can provide the best-customized solutions for your product development.

Free Consultation

Before starting your project, our experts will help you to evaluate and compare different proposals. Finally, we will work out together for the best solution.

Turn Key Solution

Reliance machinery provides a one-stop turnkey solution for roll forming machinery. It will be helpful for you to successful start up a new project.

1 Year Warranty

18 months after shipment or 12 months after installation and commissioning at your factory, whichever comes first will be deemed as the period of warranty.

Full Supported Services

The reliance full support services team provides full-lifecycle services to provision, run, and support your roll forming machine working.

Quick Response

Once we receive calls or emails from customers, we will reply in the first time and provide the solution.

Welcome to Visit Reliance Machinery

R & D Team

Aftersales Team

Machine Assembling

Spare Parts Warehouse

Machine Assembling

Steel Profiles Production

Customers Inspection

Machine Assembling

Questions You May Still Have

What do I need to provide to get a quote for roll forming machine?

We usually offer a customized solution according to customer’s drawing. Please provide the following information.

- Material thickness range.

- Material yield strength.

- Product cross-section drawing with dimensions.

If the drawing is not ready, you also can provide product photos or physical samples.

What are your payment terms?

Our regular payment term is 30% T/T down payment, 70% T/T before shipment. The irrevocable LC at sight is also acceptable. The payment term is negotiable according to the order.

What’s the delivery time for our roll forming machines?

The standard machines require 45-60 calendar days after receiving down payment. For each machine, Reliance will evaluate the production period and delivery in time.

How do you load the roll forming machines and fix inside of the container?

Through gantry crane and forklift, our experienced team can load the machines inside the container. The machines are fixed by a special container strap with tensioner. It will assure the machines are well fixed and without damage to the transportation process. For spare parts, it will be put insider of the wooden box.

Could you arrange the transportation to our destination seaport?

We have a professional logistic team can arrange the shipment directly to your seaport or city. It will save your time and cost to arrange transportation.

Could you send engineers to startup roll forming machines?

After machines arriving at your factory, we can send technicians to install, commission, and train your operator. You need to prepare the power supply, lifting equipment, hydraulic oil, and raw material.

What is the warranty on your roll forming machines?

18 months after shipment or 12 months after installation and commissioning at your factory, whichever comes first will be deemed as the period of warranty. This guarantee excludes any parts that require normal maintenance.

Do you have any certificates for roll forming machines?

Our roll forming machines are made according to CE standards and get a CE certificate for exporting to the European market. All machine details are fabricated according to high standards.

What electricity supply does your machine need?

To adapt to the power supply in different countries, we can make electrical systems according to different voltage. Besides, the electrical control system will use the international brand and comply with your country standards.

What regular maintenance required for the roll forming machines?

Reliance will provide regular maintenance guide to help you minimizing machinery downtime and turn maximizing production time. Reliance assesses the maintenance requirements of each of your machines, based on age, usage, and type, and provide a suitable maintenance plan.

How you to my roll forming machine breakdown?

Reliance Machinery installs a remote control module to guide customers in the troubleshooting and maintenance of roll forming machines. Aftersales engineers can diagnose and troubleshoot roll forming machines in your factory.

How to select roll forming machine manufacturers?

It’s very easy to find roll forming machine suppliers from internet. Most customers will be difficult to select suppliers, and even machine photos are very similar. You can select from some important factors. The core engineer team, the metalworking machines and capacity and successful cases are basic factors for good roll forming machine manufacturers. Besides, you need to compare the details of the technical specification. For example, you can work out a comparison list for workflow, machine structure, roller and shaft material and treatment, motor brand, control system brand, etc.

What’s your roll forming machine service life?

The machine service life will be the real cost of the roll forming machine you purchased. Reliance roll forming machine will work at least 10 to 15 years vary from different working frequency. When you are buying the roll forming machine, you can’t only consider the machine price, please also consider whether the machine quality is good enough to work for a long period.

Send Your Inquiry Now

Director Messgae

Reliance Machinery will be focus on with our clients to provide global technical sales support, top quality control and timely delivery of innovative engineered roll forming machines solutions. Our values and beliefs are generating maximize profits to annual returns and reinvestment goals of our customers in the global markets we serve.

Anson – ChienManaging Director